Starting from:

$8

Home

Linde

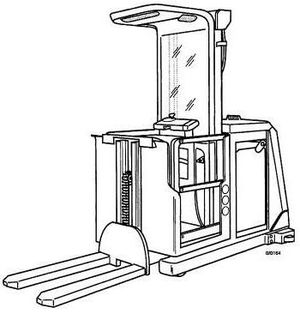

Linde E20, E25, E30 Explosion Protected Electric Forklift Truck 336-02 Series Operating Instructions

Linde E20, E25, E30 Explosion Protected Electric Forklift Truck 336-02 Series Operating Instructions

Original Illustrated Factory Operating and Maintenance Instructions for Linde Electric Forklift Truck E336-02 EX Series, Models E20-02, E25-02, E30-02.

Original factory manuals for Linde Forklift Trucks, contains high quality images, diagrams and instructions to help you to operate, maintenance and repair your truck

Covered models:

E20

E25

E30

Format: PDF, 96 Pages

Language: English

Contents:

Foreword

Proper usage

Unapproved use

Description of use and climatic conditions

Receiving the industrial truck

EC declaration of conformity

Description

Type plates

Technical data

Noise emission value

Frequency characteristic for human body vibrations

Technical description

Drive

Steering

Hydraulic system

Operation

Brakes

Handbrake

Brush monitor

Check the insulation resistance

Insulation resistance warning

Insulation resistance fault

Wheels

Electrical system

General view of truck

Controls and indicators

Composite instrument

Hour meter

Battery discharge indicator

Indicator lights

Overheating warning light

Reverse direction warning light

Insulation monitor indicator light

Motor brush warning light

Beginning operation

Safety rules

Specialist

Safety information

Operation of industrial trucks in the plant area

Handling fluids and lubricants

Periodic safety inspection

Explosion protection inspection

Running-in instructions

Daily checks and services before operation

Checks and services prior to initial operation of the truck

Daily checks

Tighten the wheel fasteners

Check the condition for leakage resistance of the tyres

Opening the overhead guard

First lock-in position: Servicing position

Second lock-in position: Battery change

Closing the overhead guard

Disconnecting the battery plugs

1st version

2nd version

Connecting the battery plugs

1st version

2nd version

Checking the battery state of charge

Charging the battery

Connect the battery to a suitable external charger

Check the condition, electrolyte level and specific gravity of the battery

Battery change

Battery removal with a crane

Adjusting the driver`s seat

Applying the seat belt

Opening the seat belt

Turning on the key switch

Turning off the key switch

Check the braking system

Check the horn

Depress emergency isolator button

Unlock emergency isolator button

Inspect the forks

Operation

Driving

Travel in the forward direction

Travel in the reverse direction

Reversing the direction of travel

Malfunctions during operation

Single-pedal model

Steering system

Steering

Braking system

Service brake, electric brake

Foot brake

Operating the electric motor brake (LBC)

Handbrake

To engage the handbrake

To release the handbrake

Operating the horn <g

Wiper operation

Operating the manual wiper <g

Operating the electric wiper <g

Turning the wiper on

Turning the wiper off

Turn signal lever <g)

Turning on the turn signal lights

Lighting <g

Turning on the lighting

Turning on the spotlight

Flasher

Stop lights

Fuses

Energy-saving feature

Opening the electrical compartment cover

Closing the electrical compartment cover

Control lever (joystick) for mast and attachments

Tilting the mast forward

Tilting the mast back

Raising the fork carriage

Lowering the fork carriage

Operating the attachments

Operating the sideshift

Operating the clamp

Single control lever operation of mast and attachments

Before loading

Loading

Positioning the forks

Transporting the load

Unloading

Before leaving the lift truck unattended

Wheel change

Jack locations

Changing the rear wheels

Changing the front wheels

Transport, Hoisting the truck

Transport with lorry or low-bed trailer

Hoisting the truck with a crane

Hoisting the truck with the eyebolts

Towing instructions

Towing the truck

Towing procedure

Mast removal

Tilting the mast manually

Lowering the fork carriage manually (Ex protection zone 2)

Lowering the fork carriage manually (Ex protection zone 1)

Tow coupling

Forced opening of overhead guard

without Bowden cable

Emergency exit for trucks with rear windscreen

Emergency exit for trucks with polycarbonate rear windscreen

Taking the truck out of operation

Measures before taking the truck out of operation

Putting the truck back into operation

Disposal of old vehicles

Maintenance

General information

Mast versions

Work on the mast and on the front part of the truck

Securing the mast against tilting back

Standard mast

Securing the raised standard mast

Duplex mast

Securing the raised duplex mast

Triplex mast

Securing the raised triplex mast

Services after the first 50 hours of operation

Inspection and maintenance chart

Inspection and maintenance as required

Check seat belt for condition and operation

Clean the lift truck

Clean and spray the lift chains

Tighten the wheel fasteners

Check the tyres for damage and foreign objects

Check the security of the hydraulic oil tank

Check the insulation monitor

Renew the motor brushes

Lubricate the steering axle, mast and tilt cylinder bearings

500-hour inspection and maintenance

Clean the steering axle

Lubricate the steering axle

Lubricate the mast and tilt cylinder bearings

Sideshift: Clean, grease and check for security

Tighten the mast fastening bolts

Grease the overhead guard pivots

Check and lubricate other pivots and joints

Check the mounting of the counterweight, electric motors, chassis, reduction gears, overhead guard and steer axle

Check the braking system

Check the working and steering hydraulic pumps, valves and lines for leaks

Clean the left and right wheel traction motors, the power steering and working hydraulics pump motor

Check the motor brushes, renew if necessary

Check the hydraulic oil level

Check and oil the pedal and travel control linkage pivots and overhead guard lock

Check the electric cables, cable connectors and connections for condition and tightness

Check the contactor tips <g

Change the reduction gear oil

Mast, lift chain and end stops:

Check for condition, security and proper operation

Adjust the lift chain length, lubricate the lift chain with chain spray

Check the forks and fork quick-releases

Check the pre-tension of double hoses if attachments are fitted

Renew the hydraulic system breather, suction and pressure filters

1500-hour inspection and maintenance

Renew the breather filter

Change the pressure filter

Renew the suction filter

Check the reduction gearboxes for oil leaks

3000-hour inspection and maintenance

Renew the hydraulic oil

Change the oil in the reduction gearboxes

Inspection and maintenance data

Lubricant recommendations

Hydraulic oil

Bio-hydraulic oil

Lubricating grease

Battery grease

Gear oil

Chain spray

Vaseline

Troubleshooting guide

Hydraulic schematic for working and steering hydraulics

Wiring diagram

Optional equiment

Index

Original factory manuals for Linde Forklift Trucks, contains high quality images, diagrams and instructions to help you to operate, maintenance and repair your truck

Covered models:

E20

E25

E30

Format: PDF, 96 Pages

Language: English

Contents:

Foreword

Proper usage

Unapproved use

Description of use and climatic conditions

Receiving the industrial truck

EC declaration of conformity

Description

Type plates

Technical data

Noise emission value

Frequency characteristic for human body vibrations

Technical description

Drive

Steering

Hydraulic system

Operation

Brakes

Handbrake

Brush monitor

Check the insulation resistance

Insulation resistance warning

Insulation resistance fault

Wheels

Electrical system

General view of truck

Controls and indicators

Composite instrument

Hour meter

Battery discharge indicator

Indicator lights

Overheating warning light

Reverse direction warning light

Insulation monitor indicator light

Motor brush warning light

Beginning operation

Safety rules

Specialist

Safety information

Operation of industrial trucks in the plant area

Handling fluids and lubricants

Periodic safety inspection

Explosion protection inspection

Running-in instructions

Daily checks and services before operation

Checks and services prior to initial operation of the truck

Daily checks

Tighten the wheel fasteners

Check the condition for leakage resistance of the tyres

Opening the overhead guard

First lock-in position: Servicing position

Second lock-in position: Battery change

Closing the overhead guard

Disconnecting the battery plugs

1st version

2nd version

Connecting the battery plugs

1st version

2nd version

Checking the battery state of charge

Charging the battery

Connect the battery to a suitable external charger

Check the condition, electrolyte level and specific gravity of the battery

Battery change

Battery removal with a crane

Adjusting the driver`s seat

Applying the seat belt

Opening the seat belt

Turning on the key switch

Turning off the key switch

Check the braking system

Check the horn

Depress emergency isolator button

Unlock emergency isolator button

Inspect the forks

Operation

Driving

Travel in the forward direction

Travel in the reverse direction

Reversing the direction of travel

Malfunctions during operation

Single-pedal model

Steering system

Steering

Braking system

Service brake, electric brake

Foot brake

Operating the electric motor brake (LBC)

Handbrake

To engage the handbrake

To release the handbrake

Operating the horn <g

Wiper operation

Operating the manual wiper <g

Operating the electric wiper <g

Turning the wiper on

Turning the wiper off

Turn signal lever <g)

Turning on the turn signal lights

Lighting <g

Turning on the lighting

Turning on the spotlight

Flasher

Stop lights

Fuses

Energy-saving feature

Opening the electrical compartment cover

Closing the electrical compartment cover

Control lever (joystick) for mast and attachments

Tilting the mast forward

Tilting the mast back

Raising the fork carriage

Lowering the fork carriage

Operating the attachments

Operating the sideshift

Operating the clamp

Single control lever operation of mast and attachments

Before loading

Loading

Positioning the forks

Transporting the load

Unloading

Before leaving the lift truck unattended

Wheel change

Jack locations

Changing the rear wheels

Changing the front wheels

Transport, Hoisting the truck

Transport with lorry or low-bed trailer

Hoisting the truck with a crane

Hoisting the truck with the eyebolts

Towing instructions

Towing the truck

Towing procedure

Mast removal

Tilting the mast manually

Lowering the fork carriage manually (Ex protection zone 2)

Lowering the fork carriage manually (Ex protection zone 1)

Tow coupling

Forced opening of overhead guard

without Bowden cable

Emergency exit for trucks with rear windscreen

Emergency exit for trucks with polycarbonate rear windscreen

Taking the truck out of operation

Measures before taking the truck out of operation

Putting the truck back into operation

Disposal of old vehicles

Maintenance

General information

Mast versions

Work on the mast and on the front part of the truck

Securing the mast against tilting back

Standard mast

Securing the raised standard mast

Duplex mast

Securing the raised duplex mast

Triplex mast

Securing the raised triplex mast

Services after the first 50 hours of operation

Inspection and maintenance chart

Inspection and maintenance as required

Check seat belt for condition and operation

Clean the lift truck

Clean and spray the lift chains

Tighten the wheel fasteners

Check the tyres for damage and foreign objects

Check the security of the hydraulic oil tank

Check the insulation monitor

Renew the motor brushes

Lubricate the steering axle, mast and tilt cylinder bearings

500-hour inspection and maintenance

Clean the steering axle

Lubricate the steering axle

Lubricate the mast and tilt cylinder bearings

Sideshift: Clean, grease and check for security

Tighten the mast fastening bolts

Grease the overhead guard pivots

Check and lubricate other pivots and joints

Check the mounting of the counterweight, electric motors, chassis, reduction gears, overhead guard and steer axle

Check the braking system

Check the working and steering hydraulic pumps, valves and lines for leaks

Clean the left and right wheel traction motors, the power steering and working hydraulics pump motor

Check the motor brushes, renew if necessary

Check the hydraulic oil level

Check and oil the pedal and travel control linkage pivots and overhead guard lock

Check the electric cables, cable connectors and connections for condition and tightness

Check the contactor tips <g

Change the reduction gear oil

Mast, lift chain and end stops:

Check for condition, security and proper operation

Adjust the lift chain length, lubricate the lift chain with chain spray

Check the forks and fork quick-releases

Check the pre-tension of double hoses if attachments are fitted

Renew the hydraulic system breather, suction and pressure filters

1500-hour inspection and maintenance

Renew the breather filter

Change the pressure filter

Renew the suction filter

Check the reduction gearboxes for oil leaks

3000-hour inspection and maintenance

Renew the hydraulic oil

Change the oil in the reduction gearboxes

Inspection and maintenance data

Lubricant recommendations

Hydraulic oil

Bio-hydraulic oil

Lubricating grease

Battery grease

Gear oil

Chain spray

Vaseline

Troubleshooting guide

Hydraulic schematic for working and steering hydraulics

Wiring diagram

Optional equiment

Index

1 file (10.2MB)